-

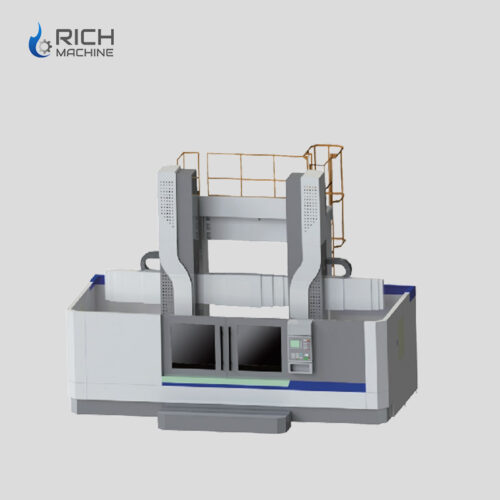

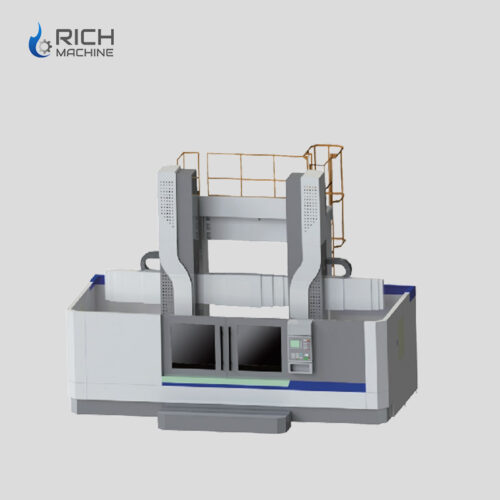

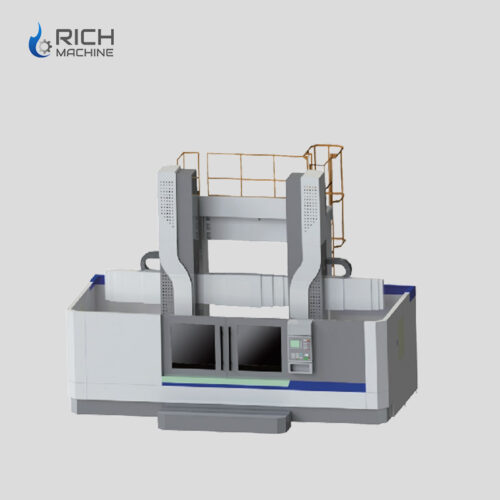

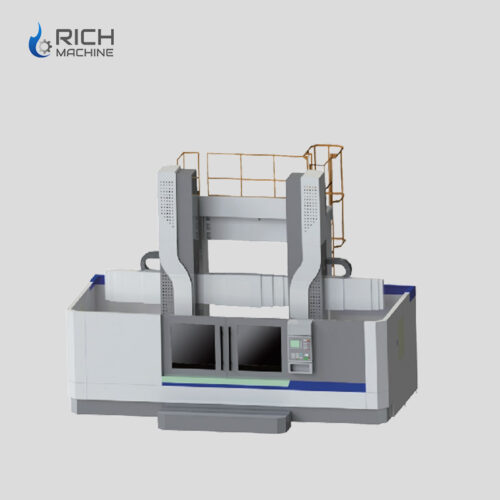

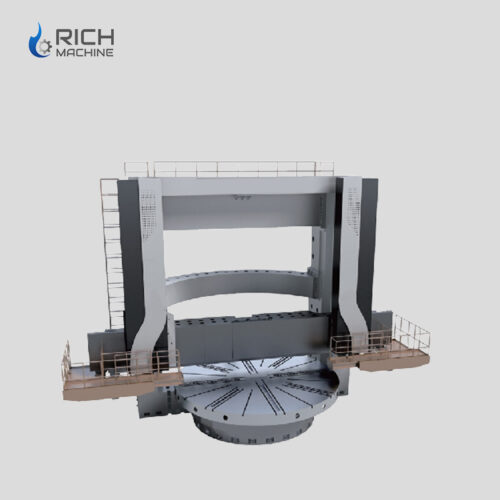

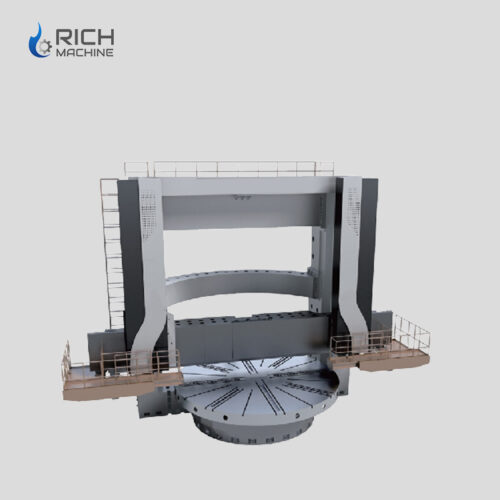

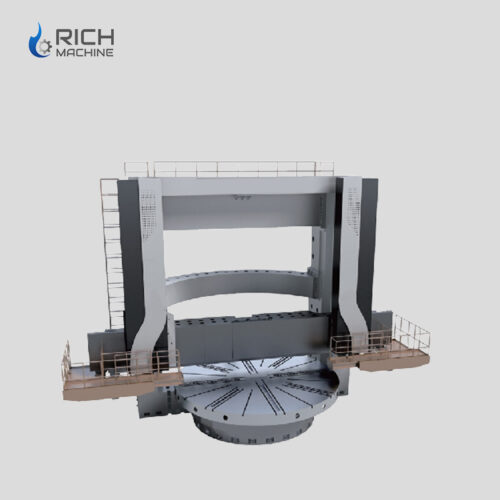

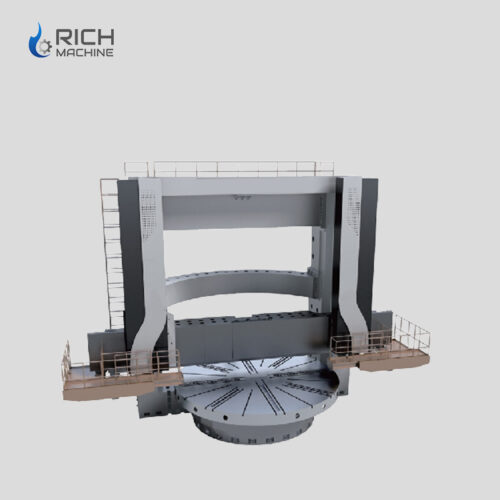

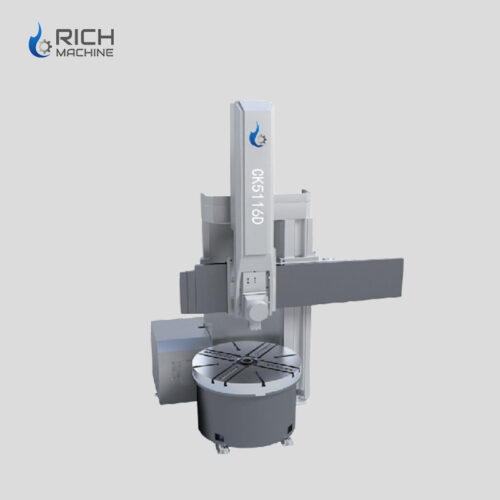

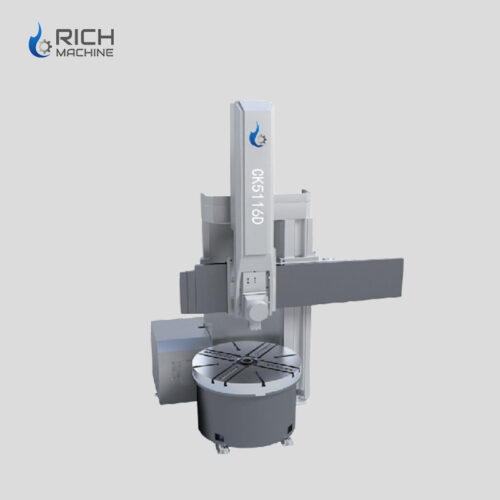

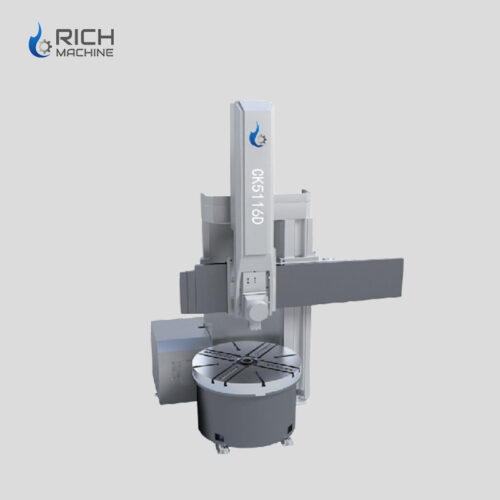

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

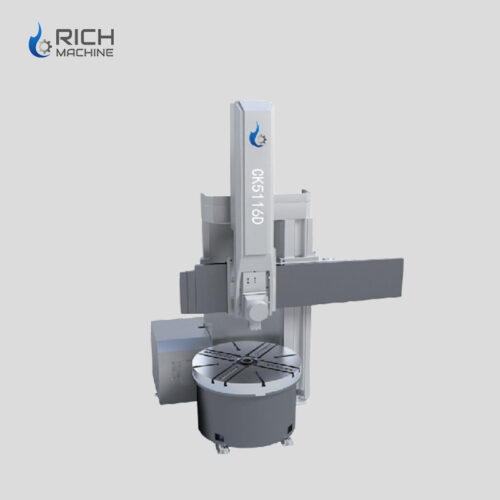

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function.

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function. -

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function.

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function. -

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function.

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function. -

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function.

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function. -

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function.

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function. -

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function.

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function. -

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function.

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function. -

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function.

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function. -

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function.

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function. -

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function.

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function. -

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function.

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function. -

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function.

Main Features: Workable unti-water design. Equiped with SIMENS 828D CNC control ( optional FANUC and GSK ) Except CNC auto running mode, you can also use it in manual way like conventional machine. Two configurations available. 4 steps gearbox plus AC variable, or 2 steps gearbox plus big torque DC stepless motor, with taping function and CSCS function. -

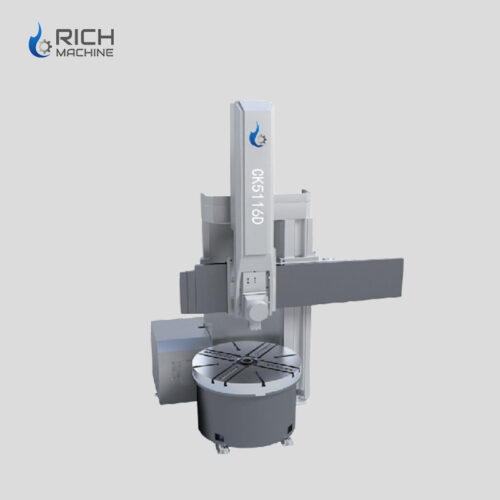

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life.

Main Features: This series of machine tools is an upgraded version of ordinary vertical lathes. It retains the original gantry frame and worktable main drive parts, cancels the traditional ordinary trapezoidal screw and light bar and self-made gear feed box, and upgrades to a servo feed motor with a planetary reducer and ball screw drive. It makes the structure simpler, the operation more convenient, and the failure rate is low. This type of machine tool is widely used in machinery, mining and metallurgy, automobiles, electricity and other industries, with stable precision, easy operation, safety and reliability, and long service life. -

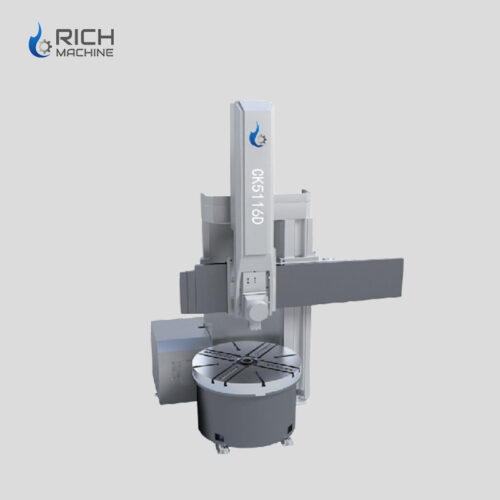

Main Features: The high rigidity design of the bottom bed is close to a square, and the influence of thermal displacement vibration is minimized. The chip removal angle of the bottom bed is increased, and stainless steel plates are added, which is conducive to better chip removal and prevents thermal deformation of the bed. The three-dimensional assembly line is ergonomically operable and easy to transport workpieces. The space occupied is 1/2 less than that of a horizontal lathe.

Main Features: The high rigidity design of the bottom bed is close to a square, and the influence of thermal displacement vibration is minimized. The chip removal angle of the bottom bed is increased, and stainless steel plates are added, which is conducive to better chip removal and prevents thermal deformation of the bed. The three-dimensional assembly line is ergonomically operable and easy to transport workpieces. The space occupied is 1/2 less than that of a horizontal lathe. -

Main Features: The high rigidity design of the bottom bed is close to a square, and the influence of thermal displacement vibration is minimized. The chip removal angle of the bottom bed is increased, and stainless steel plates are added, which is conducive to better chip removal and prevents thermal deformation of the bed. The three-dimensional assembly line is ergonomically operable and easy to transport workpieces. The space occupied is 1/2 less than that of a horizontal lathe.

Main Features: The high rigidity design of the bottom bed is close to a square, and the influence of thermal displacement vibration is minimized. The chip removal angle of the bottom bed is increased, and stainless steel plates are added, which is conducive to better chip removal and prevents thermal deformation of the bed. The three-dimensional assembly line is ergonomically operable and easy to transport workpieces. The space occupied is 1/2 less than that of a horizontal lathe. -

Main Features: The high rigidity design of the bottom bed is close to a square, and the influence of thermal displacement vibration is minimized. The chip removal angle of the bottom bed is increased, and stainless steel plates are added, which is conducive to better chip removal and prevents thermal deformation of the bed. The three-dimensional assembly line is ergonomically operable and easy to transport workpieces. The space occupied is 1/2 less than that of a horizontal lathe.

Main Features: The high rigidity design of the bottom bed is close to a square, and the influence of thermal displacement vibration is minimized. The chip removal angle of the bottom bed is increased, and stainless steel plates are added, which is conducive to better chip removal and prevents thermal deformation of the bed. The three-dimensional assembly line is ergonomically operable and easy to transport workpieces. The space occupied is 1/2 less than that of a horizontal lathe. -

Main Features: The high rigidity design of the bottom bed is close to a square, and the influence of thermal displacement vibration is minimized. The chip removal angle of the bottom bed is increased, and stainless steel plates are added, which is conducive to better chip removal and prevents thermal deformation of the bed. The three-dimensional assembly line is ergonomically operable and easy to transport workpieces. The space occupied is 1/2 less than that of a horizontal lathe.

Main Features: The high rigidity design of the bottom bed is close to a square, and the influence of thermal displacement vibration is minimized. The chip removal angle of the bottom bed is increased, and stainless steel plates are added, which is conducive to better chip removal and prevents thermal deformation of the bed. The three-dimensional assembly line is ergonomically operable and easy to transport workpieces. The space occupied is 1/2 less than that of a horizontal lathe. -

Main Features: The high rigidity design of the bottom bed is close to a square, and the influence of thermal displacement vibration is minimized. The chip removal angle of the bottom bed is increased, and stainless steel plates are added, which is conducive to better chip removal and prevents thermal deformation of the bed. The three-dimensional assembly line is ergonomically operable and easy to transport workpieces. The space occupied is 1/2 less than that of a horizontal lathe.

Main Features: The high rigidity design of the bottom bed is close to a square, and the influence of thermal displacement vibration is minimized. The chip removal angle of the bottom bed is increased, and stainless steel plates are added, which is conducive to better chip removal and prevents thermal deformation of the bed. The three-dimensional assembly line is ergonomically operable and easy to transport workpieces. The space occupied is 1/2 less than that of a horizontal lathe.